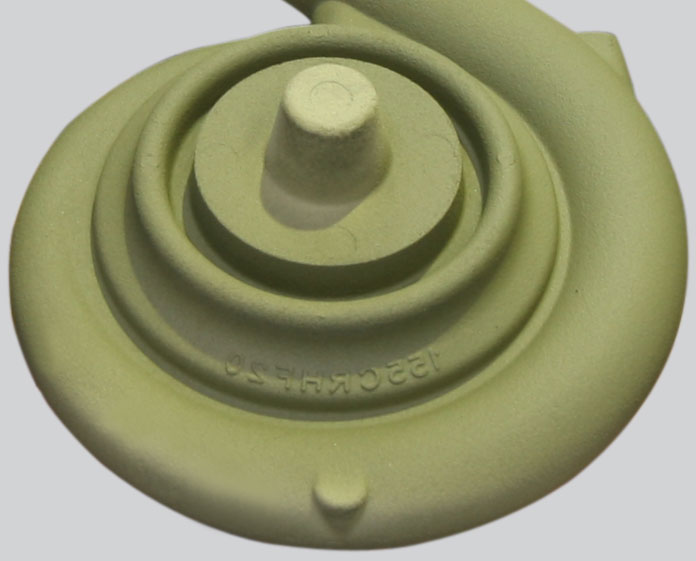

Pre.ma S.r.l. opened in 1976 and began its activity with the forming of cores using the process of shell-moulding. Two years later, in 1978, the production of cores using the process of cold box was added.

Year by year, Pre.ma S.r.l. developed significantly. The decisive factors that helped in this development were the moving of the productive plant to Montebello Vicentino in 1990, its enlargement in 2007 and the modernization of the production plants in the year 2014, with the installation of new machinery for the preparation of compounds. The new machinery allows a constant control of the various productive phases, to manage many different formulas based on customer requirements (dosing and weighting of sands, additives, binders), and to keep record of consumptions and of mixtures employed in each operation.

This development was also possible thanks to the importance that the Management of Pre.ma S.r.l. attached and still attaches to the quality of its products, to the technological development and to the customer satisfaction.

Another decisive factor for the Company is the “human factor”, that particular system of professionalism and competence that can be achieved only with experience and dedication to this work.

It is also important to remember the network of partners that can supply the customer with the best solutions.

It is for all these reasons that many important foundries have chosen Pre.ma S.r.l. as their qualified supplier. This decision has been reached after having seen and appreciated the care that the Company takes in pursuing a high quality production and an efficient service and the considerable economic efforts of the owners for the constant updating of the production processes and of the plant.

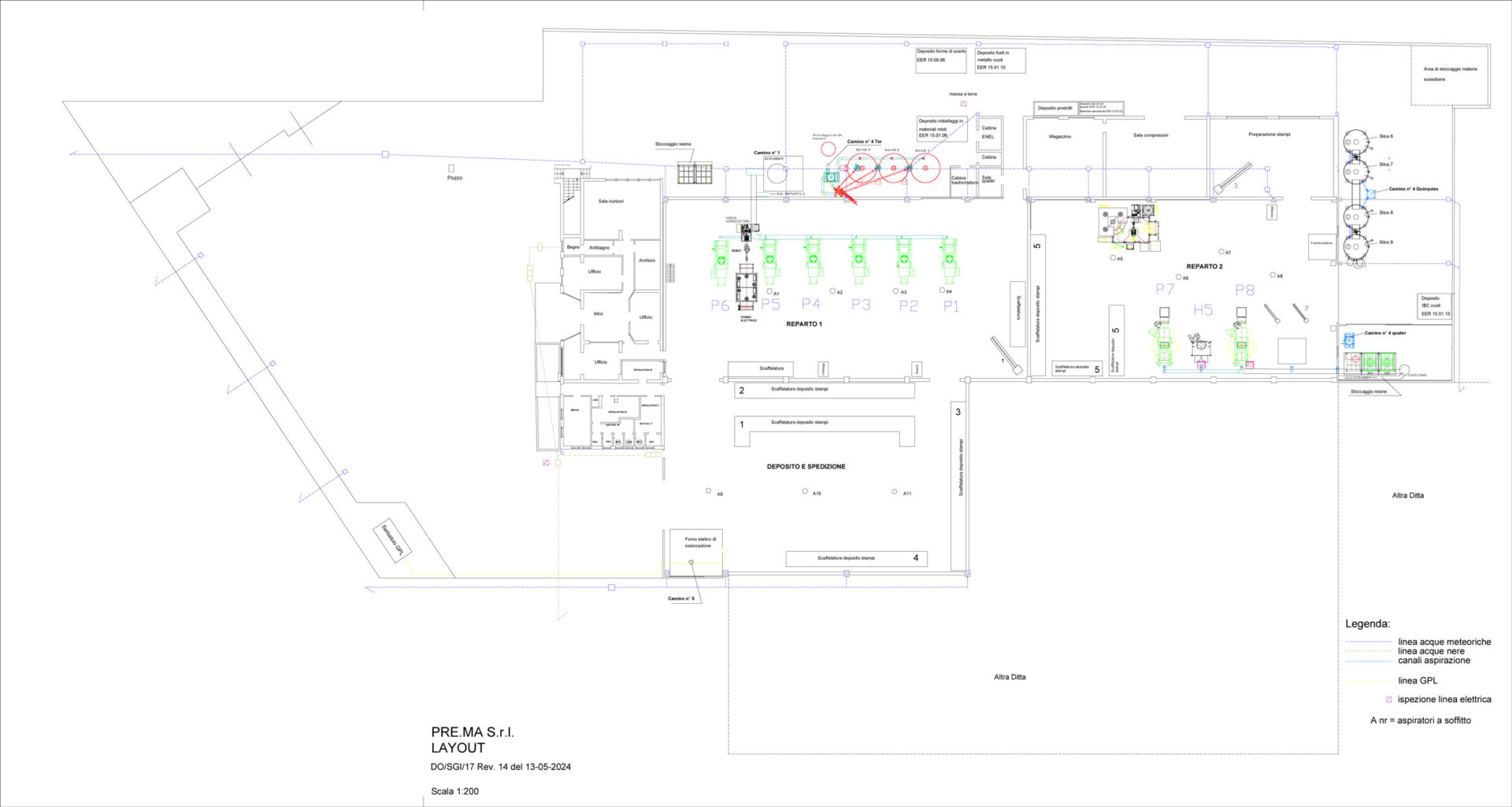

Nowadays, Pre.ma S.r.l. works in a modern operating plant: its total surface is of 5.880 square meters of which 2241 square meters are a covered floor area and are divided in: the magazine (667 square meters), productive areas (1374 square meters), offices, services and changing rooms (200 square meters).

In brief:

8.000 Tons of finished cores

Maximum flexibility of production:

it is possible to use and mix different types of sand;

it is possible to use additives;

it is possible to coat the cores.

Standards:

ISO 9001

ISO 14001

Personnel 2010:

30 employees divided in 2 shifts

average of working years in Pre.ma S.r.l.: 10 years